Serialized Folding Cartons

Variable Data

Folding Cartons

Folding Cartons - Variable Data

Variable Data adds different data sets or images to a folding carton. As packaging buyers continue to search for ways to engage customers, variable data printing provides an opportunity to change the customer experience from one printed label to the next.

Variable data printing has the ability to produce different text, images, and graphics keep cartons interesting or as an excellent way to create a unique identifier.

Some of the benefits of Variable Data Folding cartons are as follows:

- Unique barcoding

- Interchangeable text

- Variable Images

- Variable Graphics

- Increased personalization

Folding Cartons reference guide

Pros

- Cost effective – more boxes can be run at one time on the same sized paperboard as opposed to straight tuck end

- Reduced waste

- Easy assembly

- Stores flat for excess packing inventory

- Quick to load your product in packaging

- Works well for lighter weight products

Cons

- Not good for heavy products

- Visible raw edges in the front of the box

Choose Your Product

Browse our curated library of custom boxes, packaging, and other custom printed products and put together a list of products that would work for your project. Remember to bookmark your favorite products or add them to your Add to Quote Cart along with all your dimensions and custom options to keep track of what you are interested in. Once you have made your choices, you can send in your quote request to get started with your packaging journey. Alternatively, if you are looking for something that you can’t find in our library, you can visit our Request a Quote page and send in a custom quotation.

Request a Quote

Once you have sent your quote request through our Add to Quote Cart or Request a Quote page with all your product specifications, our product specialists will get started on preparing your quote. Simple quotes can be ready and sent back to you in as little as 1-2 business days. For more complicated projects that require custom structural or material sourcing may take longer. Your dedicated product specialist will reach out to you to keep you connected throughout the entire packaging process.

Place Your Order

Once you have received your quotation from our product specialist, please review it to make sure all details for your quotation are correct. For additional questions regarding your quotation, you can always speak with your product specialist for more information. When you are satisfied with your quotation and are ready to proceed, pay using our secure payment portal, which our product specialists will provide. Once your order is placed, our structural designers will promptly prepare your custom dielines!

Get Your Custom Dielines

Once your order has been placed, a dieline or artwork template file will be required for your artwork placement. For simple dielines, our structural designers can prepare your file within 1-2 business days. However, more complicated structures will require additional time and may require a design fee. Most of our custom dieline files contain structural information which allows us to prepare a 3D digital mockup of your packaging once you have placed your artwork onto the file. This allows you to preview your packaging prior to mass production to make necessary changes or corrections.

Prepare Your Artwork Designs

Get your creative juices going because you are now ready to start designing your artwork on our custom dielines. Be sure to follow the artwork guidelines on our General Artwork Guide to mitigate any issues when going into mass production. When your artwork is completed, upload your updated file to your product specialist. Our specialized artwork designers will proof your artwork and prepare a 3D digital mockup of your packaging for you to confirm before starting the production of your order.

Begin Production

Once you have approved everything, the mass production of your packaging will begin! Throughout this stage, our product specialists will keep you connected with updates of manufacturing and shipping!

Broad Capabilities Embellishments

- Spot Coatings Embossing Foil Stamping Braille

- Beneficial Results

- Every Carton is Unique

- Serialization Lot/Batch/Expiry

- Personalization Customization

Value Added

Security Features 100% Inspection No MOQ’s

| Material Options | 18PT (300 GSM) SBS / 24PT (400 GSM) SBS 18PT (300 GSM) Kraft / 24PT (400 GSM) Kraft 18PT (300 GSM) Metallic / 24PT (400 GSM) Metallic |

|---|---|

| Print Options | Offset Printing (CMYK 1 sided front / CMYK 2 sided) Up to 4 PMS Colors (Optional) |

| Special Finishes | AQ (Semi-gloss) / Gloss Varnish / Matte Varnish / Gloss Lamination / Matte Lamination / Soft Touch Spot UV + Matte Varnish / Spot UV + Matte Lamination |

| Default Process | Gluing / Die Cutting (Partial Cut, Full Cut, and Score) |

| Optional Process | Additional Cut Out / Debossing / Embossing / Foil Stamping / Perforation / Window Patching |

| Sample & Prototyping | Dieline & Digital Artwork CTP Proof Digital 3D Sample (Optional) No Print Plain Sample (Optional) Digital Print Sample (Optional) Production Sample (Optional) Please Note: All submitted artwork will go through a stringent Dieline & Digital Artwork Proof by our production specialists. For more information on other Sample & Prototyping options please visit here. |

| Shipping | Ships flat in box. Email notification with tracking information. |

| Production Lead Time | 10 – 25 business days. Production time is subject to change based on order size. For rush orders, please Contact Us for details. |

If your artwork files do not meet our specifications, PakFactory is not responsible for any printing errors that can arise as a result. Read our Artwork Preparation Guide on how to prepare your files for submission or Contact Us to have a packaging specialist help!

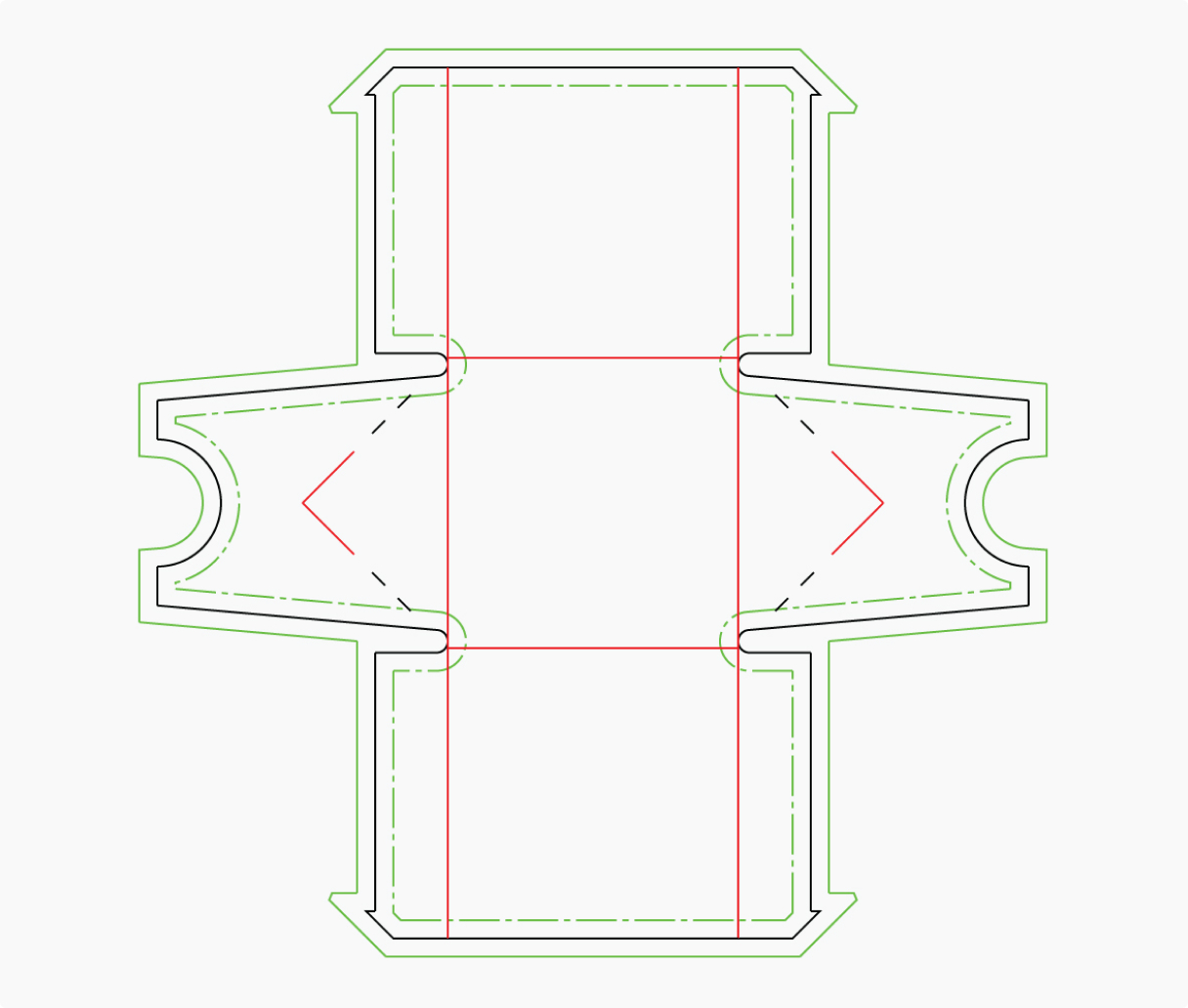

Cut Line (Black Lines):

Indicates the cut at its final size. Important artwork and text should be placed at least 0.125 inches inside of the cut line.

Crease Line (Red Lines):

Indicates where the product is to be folded.

Bleed Line (Green Lines):

Indicates where the bleed line is located. Any artwork which goes to the cut line should be extended to the bleed line to get a seamless print.

Safety Margin(Dotted Green Lines):

Indicates where artwork and text should safely be placed inside. As an industry standard, all artwork should at least be placed 0.125 inches away from the cut line unless your design is intentional.

Perforation (Dotted Black Lines):

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Choose Your Product

Browse our curated library of custom boxes, packaging, and other custom printed products and put together a list of products that would work for your project. Remember to bookmark your favorite products or add them to your Add to Quote Cart along with all your dimensions and custom options to keep track of what you are interested in. Once you have made your choices, you can send in your quote request to get started with your packaging journey. Alternatively, if you are looking for something that you can’t find in our library, you can visit our Request a Quote page and send in a custom quotation.

Request a Quote

Once you have sent your quote request through our Add to Quote Cart or Request a Quote page with all your product specifications, our product specialists will get started on preparing your quote. Simple quotes can be ready and sent back to you in as little as 1-2 business days. For more complicated projects that require custom structural or material sourcing may take longer. Your dedicated product specialist will reach out to you to keep you connected throughout the entire packaging process.

Place Your Order

Once you have received your quotation from our product specialist, please review it to make sure all details for your quotation are correct. For additional questions regarding your quotation, you can always speak with your product specialist for more information. When you are satisfied with your quotation and are ready to proceed, pay using our secure payment portal, which our product specialists will provide. Once your order is placed, our structural designers will promptly prepare your custom dielines!

Get Your Custom Dielines

Once your order has been placed, a dieline or artwork template file will be required for your artwork placement. For simple dielines, our structural designers can prepare your file within 1-2 business days. However, more complicated structures will require additional time and may require a design fee. Most of our custom dieline files contain structural information which allows us to prepare a 3D digital mockup of your packaging once you have placed your artwork onto the file. This allows you to preview your packaging prior to mass production to make necessary changes or corrections.

Prepare Your Artwork Designs

Get your creative juices going because you are now ready to start designing your artwork on our custom dielines. Be sure to follow the artwork guidelines on our General Artwork Guide to mitigate any issues when going into mass production. When your artwork is completed, upload your updated file to your product specialist. Our specialized artwork designers will proof your artwork and prepare a 3D digital mockup of your packaging for you to confirm before starting the production of your order.

Begin Production

Once you have approved everything, the mass production of your packaging will begin! Throughout this stage, our product specialists will keep you connected with updates of manufacturing and shipping!

Overview on Folding Cartons

CCL Healthcare offers cost-effective solutions with our unmatched design capabilities. Our experienced production and quality control personnel deliver the highest quality cartons. CCL Healthcare offers the ability to order what you want when you need it — eliminating inventory obsolescence. Our automated front-end and investment in custom machinery enables us to deliver customized folding cartons in high-mix/low to medium-volume quantities in turnaround times that are unparalleled in the industry without sacrificing quality. The variety of features offered by our high-tech presses allow for a broad range of capabilities such as embellishments, spot coatings, embossing, braille and security features. It also has capabilities for unique customizations such as serialization, lot/batch/expiry, personalization, and more!

With multiple Healthcare sites we provide an immediate back-up for continuity as well as a perfect partner for launching in different regions at the same time.

Browse other Folding Cartons Features

The CCL Advantage

Automation

Front-End Automation

Quality Assurance

Highest Quality Standards

Structure Design

Innovative Structure Design

Speed-to-Market

Exceptional Speed-to-Market

Why Choose CCL Healthcare for Folding Cartons?

CCL Healthcare utilizes proprietary software that streamlines the quoting, ordering, design turn around, production, and finishing process to reduce lead times which allows CCL Healthcare to offer no minimum order quantities (MOQ’s). Our automated front-end and investment in custom machinery enables us to deliver customized folding cartons in high-mix/low to medium-volume quantities in turnaround times that are unparalleled in the industry without sacrificing quality. Quality is built into everything we do and that is why we have invested heavily into 100% electronic inspection systems that allow us to detect the smallest defects and automatically remove the cartons from the production run ensuring we deliver superior quality first time every.

Contact Us

Contact a Packaging Specialist.

Request a Quote

Do you need a quote for Folding Cartons?

Order Online

Order Folding Cartons online.